With all the progress we've seen in artificial intelligence over the last few years, you could say that machines are getting smarter all the time.

Even so, most of the robots in our factories still require a fair amount of preprogramming for them to recognize the objects they handle.

That could soon be a thing of the past as researchers at MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed a system that allows robots to identify, pick up, and handle objects they haven't encountered before.

- The best robot toy gifts 2019

- The best robot vacuums of 2019

- How to make a robot with real personality

According to The Robot Report, "the team’s major insight was to look at objects as collections of 3D keypoints that double as a sort of “visual roadmap.”

The two most common approaches for robots picking up objects are pose-based systems (which estimate the object's position and orientation), and geometry-based general grasping algorithms.

These can work well under certain conditions, but both have their drawbacks. A system based on poses can't cope well with objects that are very different shapes, and grasping approaches can't position objects with much subtlety.

Visual roadmaps

The new system, which is called kPAM (Keypoint Affordance Manipulation), enables robots to carry out tasks like hanging mugs on a rack or putting shoes on shelves, without having seen the objects before.

The study's senior author, Russ Tedrake, explains that "understanding just a little bit more about the object — the location of a few key points — is enough to enable a wide range of useful manipulation tasks."

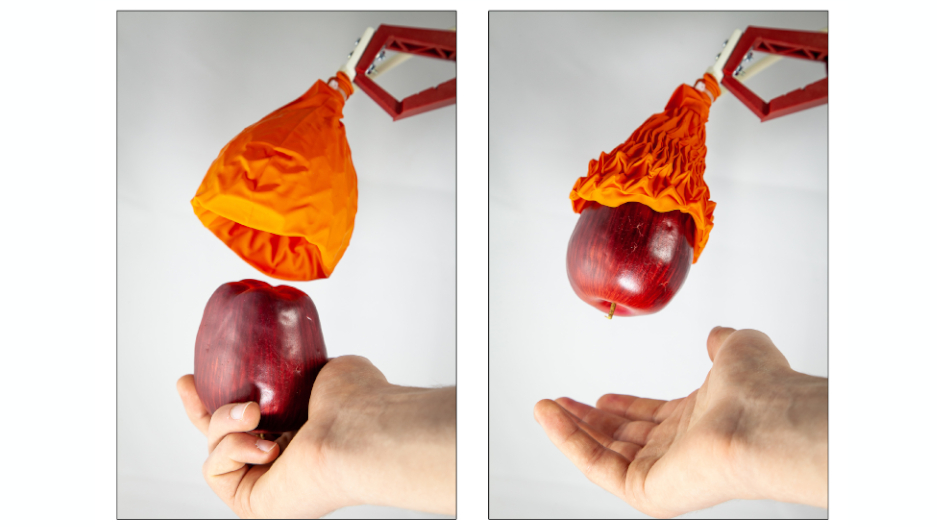

Researchers at the same laboratory created this robot hand recently.

Image credit: Jason Dorfman / MIT CSAIL

The Robot Report says that "the team next hopes to get the system to be able to perform tasks with even greater generalizability, like unloading the dishwasher or wiping down the counters of a kitchen."

While kitchen-cleaning robots sounds like an attractive proposition, the technology developed in this study could have a huge impact on factory machines, reducing the need for pre-programming, and making the manufacturing process more efficient.

Still, the technology is still in its early stages, so we aren't likely to see kPAM integrated into factory machines for a few years at least.

Via The Robot Report